CORROSION PROTECTION SOLUTIONS

Marine Corrosion Protection

Salt spray and changes in temperature and humidity subject all electrical and close tolerance mechanical assemblies such as bearings, actuators, airline connections and high voltage mating, switches and contactors to extreme conditions. The failure of any of these components present potential dangers to equipment and passengers.

Most people associate corrosion control with rust, which only happens in things made of ferrous metals such as steel girders, ships, iron pipes, steel reinforcement rods, and steel tanks and is the reason metals deteriorate and fail. Ferrous and non-ferrous metals corrode on contact with both fresh and saltwater as well as water vapour. They will also corrode when they come into contact with chemicals, liquid acids as well as acidic vapours, salts and bases, and bacteria.

Specially Formulated Anti-Corrosive Inhibitors

The ultimate defence against corrosion caused by sea spray

- Contains extremely long-lasting, specially formulated and proprietary anti-corrosive inhibitors that provide a superior lubrication coefficient and protect components against moisture, wear, general and fretting corrosion, surface static electricity, corona, and other electro migration problems. Particularly suited to prevent corrosion in hostile environments which are likely to be experienced in the marine industries.

- Prevents corrosive damage to electronics and other surfaces caused by exposure to the Sulfur dioxide (SO2), Nitrogen dioxide (NO2), Hydrogen Sulfide (H2S), Ammonia (NH3), Chlorine based gases (Cl2) based gases in Class III mixed gas tests as well as the thermal decomposition by product of HFC-227ea used in fire suppression systems, Hydrogen Fluoride (HF).

- Eliminates premature failure of components created by moisture, general or fretting corrosion. Reliability is increased maintenance intervals increased and costs reduced and manufacturers can save costly warranty service calls or product re-calls.

- SuperCORR A is hydrophobic, that is it repels water and forms a “self-healing” ultra-thin film barrier that prevents moisture from coming into contact with the coated electronic components. It will not only prevent moisture from coming in to contact but will displace moisture that is there already.

Case Studies

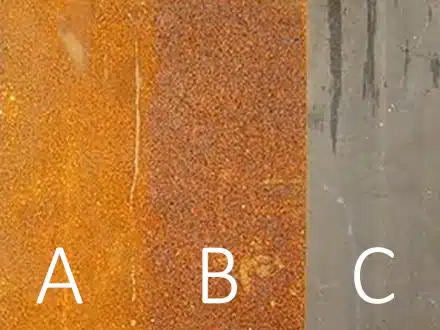

Above: Mild Steel panel exposed to sea spray on board ship for 6 months

A: Oil based CPC

B: Untreated section

C: Treated with SuperCORR A demonstrating its superior performance.

- It is clear that the use of SuperCORR A in regular maintenance procedures can bring financial savings in reduced maintenance and replacement costs and more importantly greater safety.

Above: Royal Navy Submarine

- SuperCORR A is used by The Royal Navy in submarines to prevent corrosion on components in bilges. Read the full the Royal Navy report here.

- Designed to protect and lubricate wiring connectors, terminations, lugs and leads, electrical bonds and grounds, relays, fittings, circuit boards, computers, from moisture, general and fretting corrosion, surface static electricity, corona, and other electro migration problems, antenna connections for radios, radar, exposed motors and generators, circuit breakers and electrical switching panels. Use in any areas that are prone to collect sea water such as bilges, voids, and “I” beams.

Above: Salt water spray on a US Navy Ship

- The U.S. Navy selected SuperCORR A after exhaustive testing using American Society for Testing and Materials (ASTM) Standard B117- Standard Practice for Operating Salt Spray Apparatus.

Customer service and technical support provided from qualified distributors worldwide. We can supply Safety Data Sheets, independent laboratory reports, product samples and further assistance. For more information or advice please contact us by telephone on +44 (0) 20 8281 6370 or use our contact form.

All corrosion protection products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page: