CORROSION PROTECTION SOLUTIONS

Railways and Automotive Corrosion Protection

In all forms of transportation from Amtrak trains, lightweight rail systems and for protection of equipment and services for underground tunnels and systems. Trucks to motorsport, electric cars and emergency vehicles SuperCORR A is used for protection and lubrication of connectors, electrical systems and switches and mechanical controls during servicing. The ability to displace water from exposed contacts can ensure reliable operation in extreme conditions all in one small aerosol can.

Snow and rain mixed with road salt subject all electrical and close tolerance mechanical assemblies such as bearings, actuators, airline connections and high voltage mating jumpers on trains and trucks to extreme conditions. The failure of any of these components present potential dangers to equipment and passengers

Specially Formulated Anti-Corrosive Inhibitors

The ultimate defence against corrosion

- Lubricates and protects switches in the most hostile environments which are likely to be experienced in the transportation industry.

- Unexcelled in preventing deterioration and contamination on all surfaces of

electronic and electrical equipment and mechanical close tolerance moving components. - Designed to protect and lubricate connectors, terminations and electrical bonds and grounds, relays, fittings, circuit boards, computers, from moisture, general and fretting corrosion, surface static electricity, corona, and other electro migration problems. Other areas of application include Passenger Master Control Panels, interior and exterior light sockets and any exposed metal surfaces.

- Eliminate premature failure of components created by moisture, general or fretting corrosion. Reliability is increased, maintenance intervals increased, costs reduced and manufacturers can save on maintenance and repair costs .

- Prevents the corrosive damage to electronics and other surfaces caused by exposure to the Sulfur dioxide (SO2), Nitrogen dioxide (NO2), Hydrogen Sulfide (H2S), Ammonia (NH3), Chlorine based gases (Cl2) based gases in Class III mixed gas tests as well as the thermal decomposition by product of HFC-227ea used in fire suppression systems, Hydrogen Fluoride (HF).

- SuperCORR A is hydrophobic, that is it repels water and forms a “self-healing” ultra-thin film barrier that prevents moisture from coming into contact with the coated electronic components. It will not only prevent moisture from coming in to contact but will displace moisture that is there already.

Case Studies

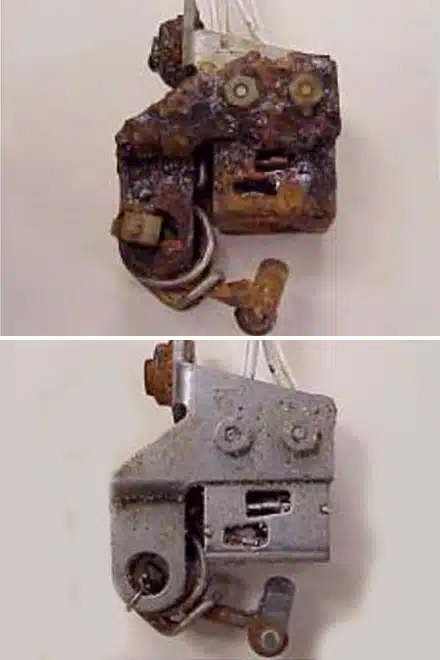

Above: Control Switches

- Top photo – Badly rusted Control Switch untreated: Electrical failure after 100 hours salt spray.

- Bottom photo – Switch treated with SuperCORR A. Passes up to 1400 hours salt spray test.

- The photographs above demonstrate how SuperCORR A lubricates and protects switches in the most hostile environments. The tests shown were carried out under controlled conditions in a hot salt spray which accelerates the results.

- The use of SuperCORR A in regular maintenance procedures can bring financial savings in reduced maintenance and replacement costs and more importantly greater safety.

Above: Amtrak Train

- Amtrak tested SuperCORR A and reported an impressive improvement in the mating of 480V car jumpers with excellent protection for connector pins and lugs with no corrosion, overheating or electrical pitting over six months.

- Preventive maintenance from one can has all but eliminated failures of lubrication and reduced maintenance costs on demanding passenger trains.

Above: Docklands Light Railway

- Electrical components, wiring and stray current corrosion is a real problem in electrified rail systems and Light Rail Transit Systems. Stray-current corrosion occurs at the point where the current leaves the connector, carrying iron ions that became positively charged when they lose one or more electrons. The damage is unseen but the effect can be major. A 1-ampere current discharging continuously from a steel pipeline will remove approximately 20 pounds of steel in a year.

- Since many LRTs are located in crowded utility corridors and in city streets with gas and oil pipelines and other underground utilities and structures, uncontrolled stray current can cause extensive damage to rail and concrete reinforcing steel, cables, and pipelines. By one estimate, stray-current corrosion damage in the U.S. may total over $500 billion annually.

Customer service and technical support provided from qualified distributors worldwide. We can supply Safety Data Sheets, independent laboratory reports, product samples and further assistance. For more information or advice please contact us by telephone on +44 (0) 20 8281 6370 or use our contact form.

All corrosion protection products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page: