Latest Articles

SuperCORR A Corrosion Protection Spray

Dry lubricant and corrosion protection spray reduces production downtime on industrial automation systems

Improving manufacturing productivity needs increasing numbers of robots, handling and positioning systems and conveyors which in factory environments need both scheduled and emergency maintenance plans to ensure continuous reliability. Failure of any part of the system will result in downtime and seriously disrupt production.

SuperCORR A from EnviroTech Europe is an innovative thin film dry lubricant spray with corrosion protective properties which does not attract dust or dirt, is stable and coats surfaces with an ultra-thin self healing, lubricant film unaffected by water or solvents and resistant to harsh corrosive atmospheres and high temperatures.

A recent case affected some clients of specialist cleaning equipment manufacturer C&C Hydrosonics a division of U.S giant Crest Ultrasonics to solve a problem occurring on x-y axis linear tracks on the Transystem automatic handling system fitted to enclosed multi tank cleaning systems both aqueous and solvent based.

Transystem automatic handling systems are programmable to automatically process baskets or jigs through liquid immersion cleaning cycles, transferring between the tanks, lowering and raising work between the tanks of cleaning liquids. The motorised carriages use nylon wheels running on case hardened mild steel tracks which can corrode during immersion and in the harsh humid atmospheres within the machine canopies.

Corrosion prevents smooth running with wheels seizing and binding on the tracks. Vibration can then cause components to be shaken from jigs or in extreme cases the carriage will stall requiring intervention by maintenance engineers to physically remove surface corrosion and re-lubricate tracks with oil. This is only a temporary measure as the oil is quickly removed by the solvents or water-based cleaning solutions with corrosion reoccurring in a short time.

Extensive trials over a six-month period with both water and solvent based systems demonstrated that SuperCORR A offered a simple solution to the problem with no corrosion of tracks or seizures during the trial period. Previously seizures needing attention occurred every few weeks now an aerosol spray of SuperCORR A is used only during normal service visits and is used as the routine lubricant during manufacture of the handling system.

Lee Casey, Managing Director of C&C Hydrosonics is delighted with the cost savings on reduced service and maintenance calls using SuperCORR A and that the inconvenience for users of the Transystem equipment has been eliminated. Use of SuperCORR A is recommended on all Crest handling systems worldwide.

Reduce maintenance costs and protect automation equipment with SuperCORR A, now available from EnviroTech Europe Ltd and distributors worldwide.

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Related Posts

Aquus CL-One Concentrated Water Based Cleaner

Concentrated water based cleaner for all applications in manufacturing, engineering and general maintenance.

Aquus CL-One cleaner is a new formulation designed to deal with all cleaning applications encountered in manufacturing and engineering. It reduces time and costs by removing the need for multiple cleaning products usually needed to deal with the challenges presented by the wide range of soils, oils and other contaminants which need to be removed. Safe for the environment and users, contains no solvents and is biodegradable within 30 days. Typical applications in industry are discussed below but many more will be experienced in day-to-day operations. With only one product for all cleaning applications incorrect selection or dangerous uses can be avoided.

Concentrated Aquus CL-One chemistry is activated by water, varying concentration levels allows the most economical solution to be chosen for specific applications from parts cleaning to surface preparations for finishing or heavier soiling on process machines all from one product. Some of the hundreds of applications are discussed below.

PARTS AND COMPONENT CLEANING

Ideally suited for cleaning protective coatings, grease and soils from new or used parts. Aquus CL-One can be used in parts washing equipment or dipping tanks without modifications and leaves no residue after drying. Oil and grease separate from the water and coalesces on the surface of the cleaning solution which can then be skimmed off for recovery and recycling. Precipitated solids free of hydrocarbons can be removed by settlement or in filtration systems. The cleaning solution can be reused continuously within its chemical parameters for efficient and economical use.

GENERAL CLEANING

Aquus CL-One is remarkably efficient removing oils, greases, and accompanying dirt from most surfaces. It can be applied by wiping surfaces, mopping or in rotary floor cleaning machines, low or high-pressure spray. Aquus CL-One is also an effective cleaner in industrial kitchens removing grease and baked on deposits on internal surfaces of ovens and trays. For maintenance of machines, engines etc oil and grease is easily removed pre and post-assembly making inspection and repair easier, quicker and cheaper by returning equipment to use.

PREPARATION FOR PAINTING OR POWDER COATING

Aquus CL-One is an excellent choice for cleaning mild steel and ferrous metal parts which are not painted immediately. Process oils and grease on the parts protect the surfaces from changes in humidity but once removed flash rusting can occur while drying. Aquus CL-One prevents this leaving an invisible barrier on the metal surfaces providing extended corrosion protection during storage, fabrication or assembly before finishing. The barrier film can be painted over without additional rinsing and without affecting adhesion of paint or powder coatings. Various cleaning systems can be used, including hand wiping, dip tanks and pressure washing.

Our applications experts and samples of the product are available by completing the contact form at our website. For more information please visit:

Share this page:

Related Posts

Corrosion control problems

Corrosion control is a serious problem for industry and governments worldwide.

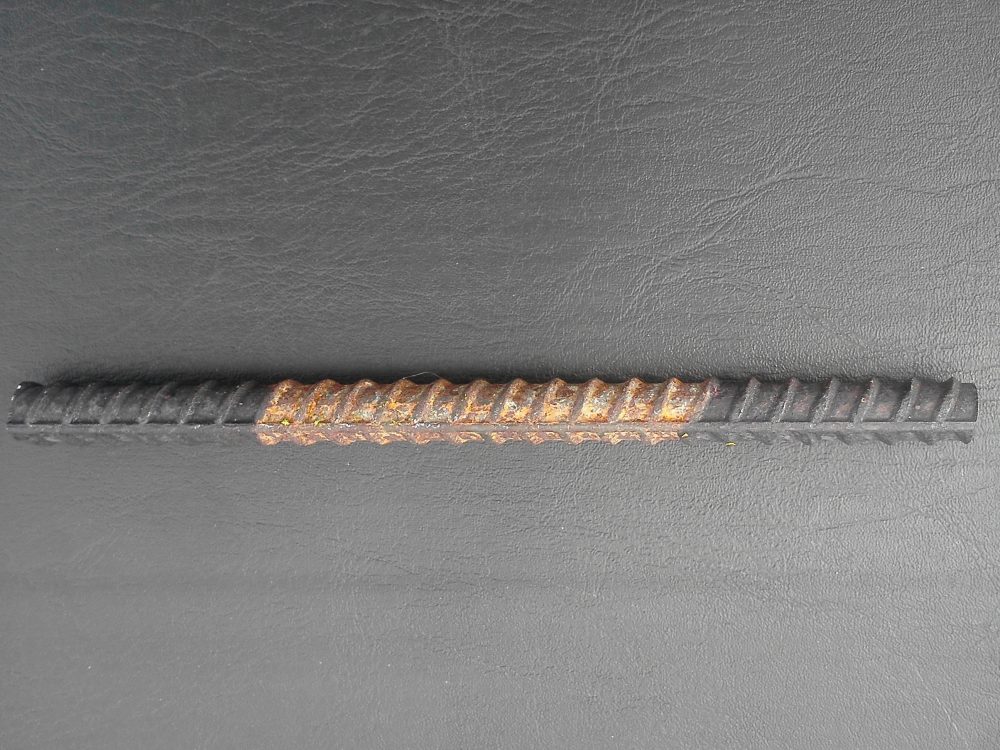

Most people associate corrosion with rust, which only happens in things made of ferrous metals such as steel girders, ships, iron pipes, steel reinforcement rods, and steel tanks and is the reason metals deteriorate and fail.

Ferrous and non-ferrous metals corrode on contact with both fresh and salt water as well as water vapor. They will also corrode when they come in contact with chemicals, liquid acids as well as acidic vapors, salts and bases, and bacteria.

Read our article “Corrosion Control Solutions – A Solution To A Costly Problem” for more information about the enormity of the costs involved in failing to prevent corrosion.

We can provide you with a Material Safety Data Sheets, independent laboratory reports, product samples and technical assistance.

For more information or advice please telephone us on +44 (0) 20 8281 6370 or use our contact form.

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Share this page:

Latest News

No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.